TALAVERA

RECEPTACLE

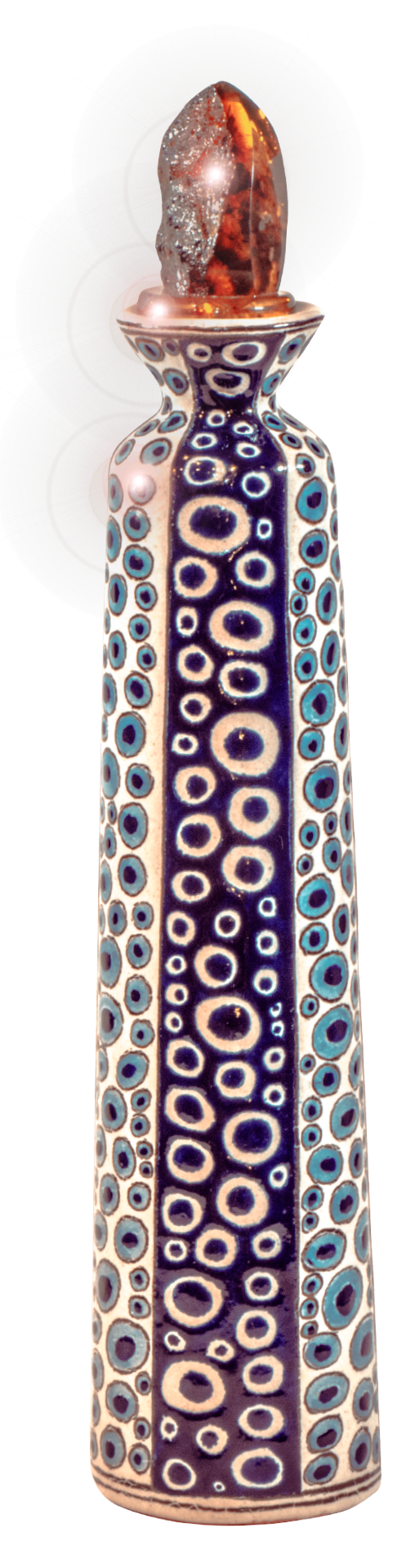

A noble spirit must be contained by the magnificence of a body at the height of its character: beauty, shape, color and emotion. For this reason, the container where our elixir lives, is conceived by potters from Puebla, ceramic masters who have been molding for 500 years, a style that gives dignity and honor to our culture. The talavera is the sculptural body that contains a pure soul.

BOTTLES MADE BY HANDS

ARTISANAL POBLANAS

Talavera is a type of majolica (common earthenware with metallic enamel) The authentic talavera from Puebla only comes from that state, specifically from the towns of Puebla de Zaragoza, Atlixco and Cholula, due to the quality of the clays found there and the the tradition of its manufacture, which dates back to the 16th century.

The design of the pieces is strictly regulated by tradition. The paint should feel to the touch with a slight rise above the base. In its beginnings, only cobalt blue was used, which was the most expensive pigment and also highly sought after, not only for prestige but because it ensured the quality of the entire piece. Talavera is the most outstanding of the artisan traditions. Only natural clays are used and not chemically treated clays. Its delicate manufacture and fragility, since a piece can break at any time, make talavera three times more expensive than any other ceramic piece.

The colors used in its decoration are blue, yellow, black, green, orange and mauve. Each piece is made by hand on a wheel, and the glaze contains tin and lead, as they have been made since the colonial era.

The process of making talavera is complicated and has practically not changed since the early colonial times. The first step is to mix black sand from Amozoc and white sand from Tecali. It is then washed and filtered to keep the finest particles. This can reduce the volume by fifty percent. The piece is then modeled by hand on a lathe, and left to dry for several days. Then comes the first firing, at a temperature of 850 degrees Celsius (1562.0 °F). After checking that it has no cracks or defects. The initial glaze or ivory-white background is applied. Subsequently, the decoration is painted by hand. Finally, it is exposed to a second firing to harden it. This process can take up to three months for most of the pieces, but in some it can take up to six. The process is complicated to such a degree that during the colonial era the potters entrusted the pieces with special prayers during the firing process.

Today, only pieces from designated areas and from specific workshops that have been certified are allowed to call their works Talavera. The certification is issued by the Talavera Regulatory Council, each certified company must go through a biannual inspection of its manufacturing processes. The pieces are subjected to 16 tests carried out by internationally certified laboratories.

On March 17, 1995, the resolution granting protection to the Denomination of Origin “Talavera de Puebla” was published in the Official Gazette of the Federation.